MCS - All modules at a glance

The MCS has a modular structure - each feature can be flexibly adapted to your production processes. Whether planning, recording, analysis or traceability: here you will find all available modules in detail.

Discover which building blocks the MCS provides to really drive your production forward.

The dashboard offers a convenient way of gaining a quick overview of the entire system. Important processes, key figures and messages are clearly displayed here.

You can see directly how many cells are currently in production, how many containers are in circulation, how many production orders are active, which transport orders are still outstanding, the current status of ongoing transports, the current status of the software modules and all system information, warnings and errors.

ADVANTAGES

The control center displays a live image of the production connected to the MCS. Current statuses are directly visible in different views.

The control center is divided into different views in order to display the hardware statuses in a clear yet detailed manner. The Work or Hall view provides an interactive 3D view in which processing cells are colored according to their status. The department overview can be accessed by clicking on the relevant department or via the main menu of the control station. The Department overview displays all processing cells in a defined grid and shows their current status in a medium level of detail. For example, you can see which product the cell is producing, which mode and status the cell has and how the status of the cell has changed in the last few hours. Clicking on a cell or via the main menu finally takes you to the machine overview. The Machine overview displays the status of a processing cell in great detail. In addition to the information from the department overview, information such as cell messages, statuses of the safety equipment (e.g. emergency stop or safety doors) and an article image are displayed here.

ADVANTAGES

In the Analyzer, key production figures can be tracked historically. Predefined evaluations are available for this purpose, which are clearly displayed on one page using various diagrams.

Our Analyzer allows users to make simple and clear evaluations of productivity, profitability and effectiveness, making it the perfect analysis tool for daily production requirements. The detailed evaluations enable you to optimize your CIP processes in a targeted manner in order to achieve maximum potential. Common evaluations such as the evaluation per area, per cell and per article or the evaluation according to scrap costs in a similar structure as well as historical system and cell errors are available as standard. These already cover the requirements of most users for an analysis tool. If the standard version leaves any wishes unfulfilled, these can be quickly and easily supplemented with customized views.

ADVANTAGES

The DMS module offers centralized management of all useful files in the familiar Explorer display.

Regardless of whether you want to make documents for customer-specific processes accessible to your users or link special maintenance documents, article images or workpiece drawings with the corresponding master data, the document management system offers you a central point of contact for such tasks. The files can be arranged in folder structures and assigned individual access authorizations. New files can simply be uploaded using the function provided or via drag and drop. The usual Explorer functions are available for managing files and folder structures.

ADVANTAGES

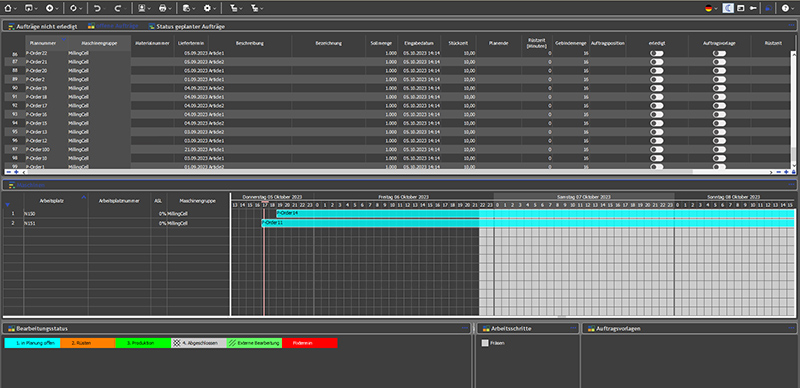

Your central point of contact for planning existing resources to achieve defined delivery targets.

In order to ensure the highest possible resource utilization and achieve the delivery targets defined in the ERP, existing resources must be optimally planned. Our planning tool offers the perfect platform for this. Depending on requirements and preferences, this tool initially supports rough planning at department level with subsequent detailed planning for the respective resources by another party or direct detailed planning. The planning tool is subdivided into Order planning, Employee planning and Shift planningwhich can be operated by one or more users as required.

ADVANTAGES

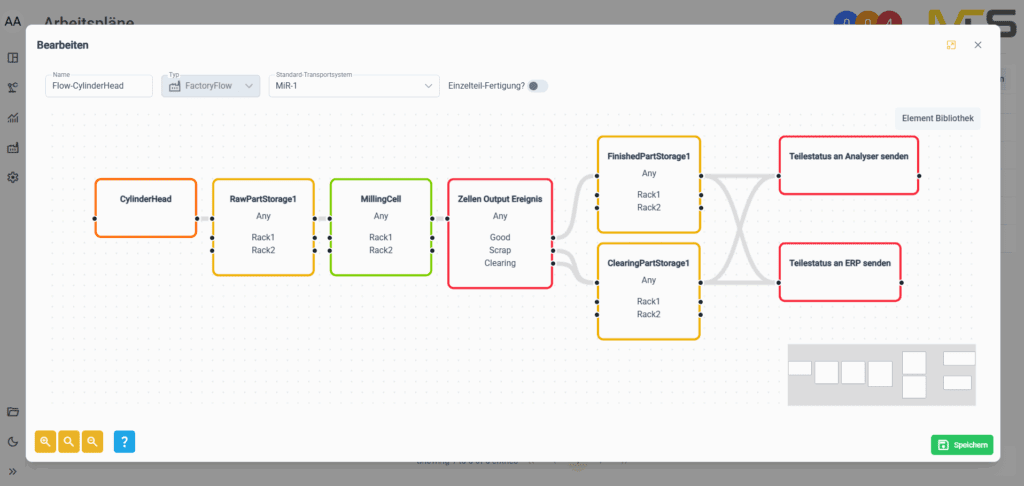

The work planner provides a convenient way to create and manage work sequences and production strategies very flexibly.

Requirements for work sequences and production strategies could not be more different. In addition, a growing company is constantly facing new challenges, which in turn entail new requirements. This makes it all the more important to have a tool available that can cover these requirements in a reliable and future-oriented manner. Our work planner offers a wide range of programming functions without requiring any programming knowledge. This is made possible by the integration of a function flow chart. This offers all the functions required for the graphical programming of work schedules via various modules. If, despite this flexibility, you still reach the limits of graphical programming, the "Custom Event" module offers the option of adding functions via JavaScript with all the advantages of the high-level language. In addition to the Production work planswhich define the production strategy of an article through the individual stations of production, there are also Cell work planswhich define the production strategy of an article within a production cell.

ADVANTAGES

The heart of the MCS. This is where the entire production cycle of each individual part is controlled and monitored. Production parameters and manufacturing information are collected and forwarded to other MCS modules for analysis and control decisions.

By taking into account all the required statuses and integrating the matrix concept, the packs are directed to the appropriate free resources in production so that they can be manufactured there. The MES takes into account the stock levels from the WMS, the production strategy from the Work planner, data from ERP and Automation interface and the planning from the Planning tool. In contrast to rigidly interlinked production, the MES of the MCS can quickly produce orders on compatible alternative resources in the event of a failure, without the need for time-consuming interventions in the system. As a result, downtimes for important orders can be reduced enormously and delivery deadlines can be met.

Manages all goods movements from picking to the finished goods warehouse across all defined intermediate steps. Operating resources and tools are also managed by the WMS.

The warehouses for workpieces, tools and operating resources can be freely created. This means that a digital twin can be created for each physical warehouse, allowing you to view all your warehouse stocks quickly and at a glance. Furthermore, storage locations can also be defined and managed for the respective object groups in the production cells. By managing the target set-up in the Work planner and the actual setup by the stock management of the cell, a dedicated setup list for the planned orders from the Planning tool are generated and processed in the user interface.

Automatically records and collects all relevant data from the machine park via an API and passes it on for visualization.

Data which is transmitted via the Automation interface are stored historically and, if required, transferred to modules such as the Control Center and the Analyzer .

Enables all relevant operating data to be recorded. Data is collected both via fully automated APIs and via user interactions in the user interface.

Operating data that is generated system-wide is managed by this module. This makes it possible to evaluate both current and historical data and to analyze it via modules such as the "Data Management" module. Control Center and Analyzer to visualize.

The intralogistics module takes care of the transportation within the system. Both a manual version and various automated versions of the module are available for this purpose.

The manual transport list can be called up via the user interface and offers all the functions required to carry out manual transports. If several people are responsible for manual transports, a user can reserve transports for themselves so that they can see which transports are still open and available. This prevents several people from wanting to carry out the same transport.

In addition to manual transport systems, automated transport systems from many manufacturers are also supported. These are mostly autonomous transport systems, also known as AGVs (autonomous guided vehicles) or AMRs (autonomous managed robots). The issuing of transport orders and status monitoring between the autonomous transport system and the MCS is implemented directly via an API. The connection of manufacturers that are not yet supported is generally possible without any problems.

By defining the compatibility of the transport transfer points, it is also possible to easily implement different manual and automated transport systems for different transport tasks. For example, different containers from different transport systems (also from different manufacturers) can be used. Depending on the manufacturer selected, there may only be restrictions here if different transport systems share the same areas on which they operate.

Forms the link between ERP and MCS.

The ERP interface is available in different versions, depending on the manufacturer and data record, and can be customized to meet a wide range of requirements. Everything is possible, from simple quantity feedback to the import of production orders with individual parameters and material requirements to the synchronization of master data. The scope of the ERP interface can therefore vary depending on requirements.

The automation interface forms the link between the automation hardware and MCS. The interface is available in various expansion stages for different requirements.

Control Center only: The smallest expansion stage, here only the current machine data is transmitted for display in the control center.

Control Center and analyzer: In this expansion stage, information about the manufactured workpieces and their condition is transferred to the Analyzer for historical evaluation in addition to the current machine data.

MCS Control: The most comprehensive expansion stage of the automation interface. In addition to the current machine data and information about manufactured workpieces, including statuses, all data required for production is also transferred here. The automation cell can request required data such as production parameters and information about the workpieces and the current container from the MCS, as well as make requests for the collection or delivery of additional containers, for example.

Ready for the next step?

Every production process is unique - which is why we are happy to take the time to answer all your questions about functions, interfaces and possible applications - openly, honestly and without obligation.

Find out how the MCS makes your production noticeably easier and more efficient.

or